LIFE-2-ACID develops a gas washer to evaluate the emissions produced during zinc recovery

AIDIMME Technological Institute continues working on the development and demonstration of the zinc and iron recovery prototype found in exhausted pickling baths in the galvanic industry.

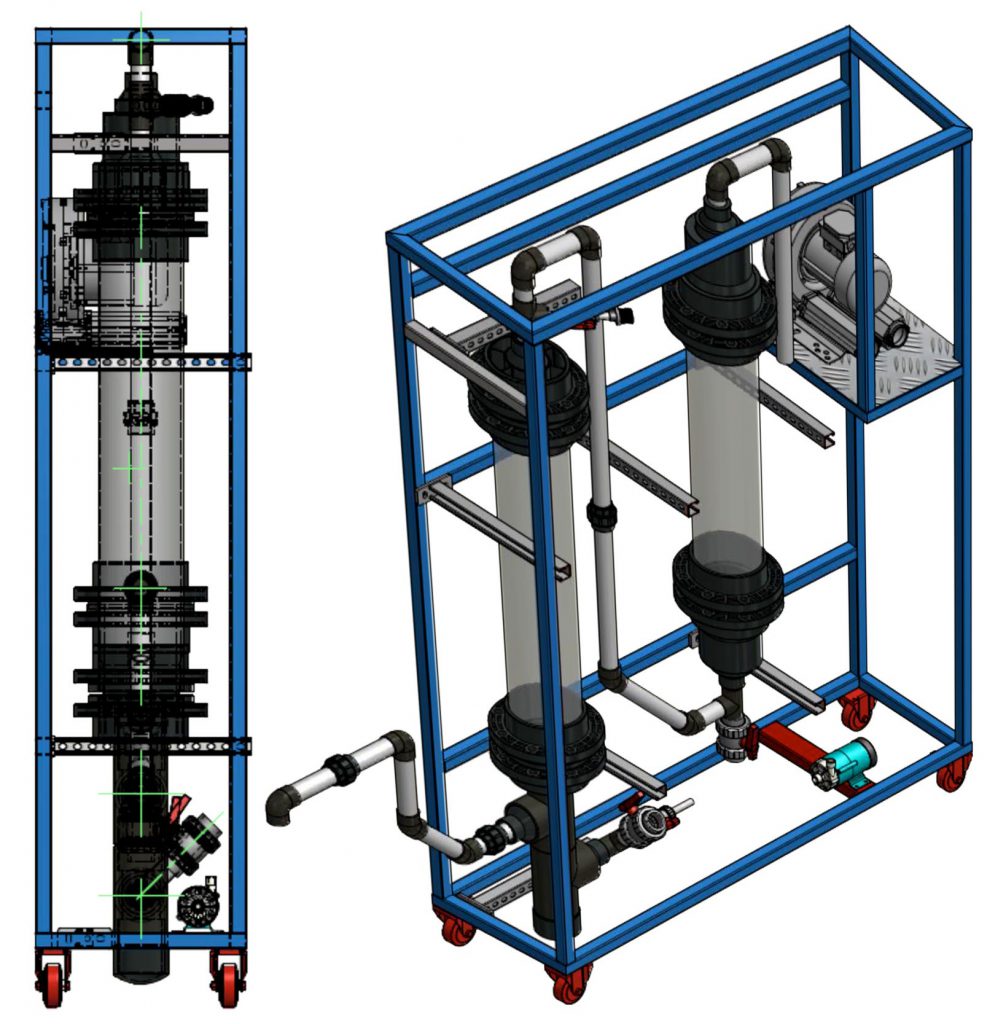

During the selective electrodeposition of zinc (image) for the exhausted baths from pickling formulated with HCl, a great amount of non-wasteful chlorine is produced, a gas generated due to the oxidation of Chlorides in the anode.

Due to the negative effect of the accumulation of this gas in the air, a gas-washer system has been designed and produced. It reduces the air impact and, in the process, makes the most of an additional by-product.

The washer is made up of a suction system connected to the electrolytic reactor and, by using a blower, the gas drives through the washing columns for a minimum retention time.

The first column is a scrubber where an alkaline solution is added and flows counter-current in recirculation through a filler with a high specific surface of Pall rings. The by-product obtained is NaOCl, a disinfectant known as ‘bleach’.

The second column is a fixed bed with a highly specific natural clay-based filling for efficient Cl2 and Cl2O gas adsorption. This column is destined to capture the residual chlorine which was not retained in the first stage.

Different organisations participate in the project: AIAS (Association of surface refinement industries), GALESA (Valencian galvanizer), MARE (EDAR), the University of Cantabria, the Universitat Politècnica de València, and AIDIMME, coordinated by APRIA SYSTEMS.

Project Number: 21700159

Grant Agreement: LIFE16 ENV / ES / 000242

Duration: From 01/07/2017 to 31/12/2021

Coordinated in AIDIMME by: BOSCH MOSSI, FRANCISCO

R&D Line: CIRCULAR ECONOMY

For further information contact AIDIMME.

Views: 129