Project EcoMarsi produces secondary raw materials for different sectors, such as Circular Economy and Industrial symbiosis in the Valencian Community

• Circular economy is one of the work fields with a highest development potential in the Valencian Community. Its implementation can optimize industrial processes, making them more sustainable and self-sufficient.

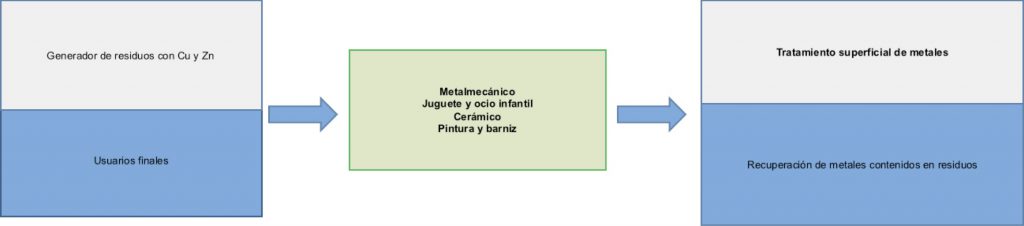

The project EcoMarsi is framed in this line of action, using industrial symbiosis between 5 sectors in the Valencian Community: surface metal treatment, children’s toys and leisure, ceramic, paint and varnish and metal mechanic.

The project’s development has allowed the production of consumer goods formulated with secondary raw materials obtained from liquid waste containing traces of Cu and Zn. The figure below shows a relational diagram of the sectors involved and their role in the value chain.

The technical execution of the projects was divided in 4 stages:

- Current characterization and recovering technologies definition

- Secondary raw materials extraction

- Consumer goods development

- Environmental product marking

In the first stage, different waste currents coming from the surface treatment sector were characterized to evaluate their metal contents, and their suitability for the recovering process. Three of these currents were selected: two of them contained Cu and one contained Zn, all of them had a metal concentration >10g/L. Moreover, different recovery processes were evaluated: electrodeposition, precipitation, exchange resins, ceramic membranes etc. After this evaluation, electrochemical deposition was selected as the best alternative to recover metals at a high purity level.

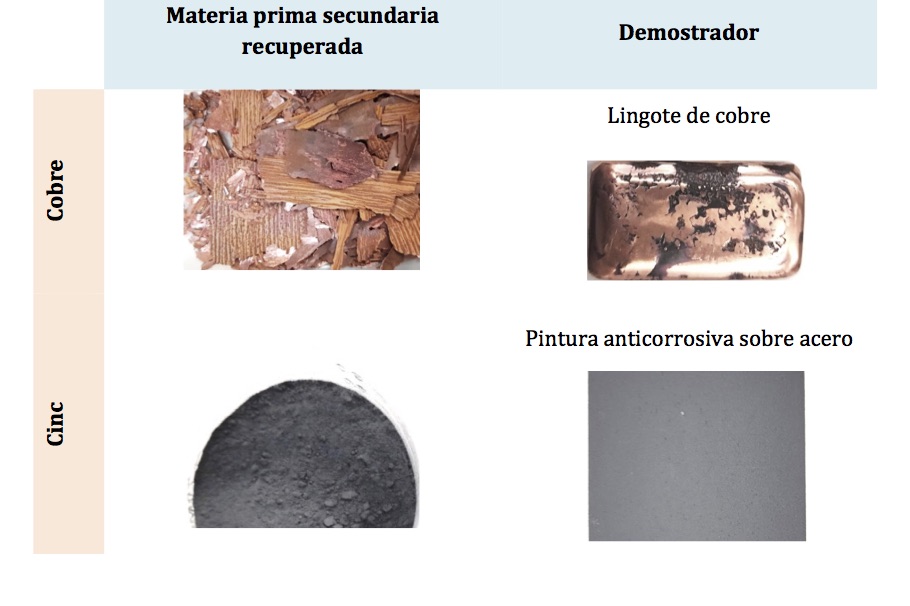

In the second stage, more than 1kg of each metal was recovered, with very high purity: >99% in the case of copper, >96% in the case of zinc. Part of the obtained metals were oxidized via a thermic treatment to obtain the corresponding copper (Cu0) and zinc (Zn0) oxides, as in the ceramic and toy sectors oxides are used as pigments and/or frites and glazes. Main technologies used for the recovery were electrodeposition and thermic oxidation. Additionally, during the project, ceramic membranes were developed, with a lower cost of production than commercial ones, for its use in the pretreatment of wastes.

In the third stage, the obtained materials were used as secondary raw materials to manufacture demonstrators of several consumer products of the different participating sectors. The figure shows a copper ingot and a steel test-tube painted with a zinc-enriched paint. Zn0 was also used as a flux in the manufacture of glazes and Cu0 for its use as a pigment in the formulation of masterbatch.

In the last stage, the possibility of using the environmental product label (eco-label), as a marketing tool applicable to products developed during the project. The conclusion was that using a type 2 eco-label (self-declaration) was a good tool to identify intermediate and final products created using secondary raw material, generated through the model of Circular Economy and Industrial symbiosis developed in EcoMarsi.

The aim of the EcoMarsi project was to show the possibilities of Industrial Symbiosis to create new and more sustainable manufacturing models, minimizing the consumption of fossil resources thanks to the synergy between different productive sectors and the use of secondary raw materials recovered from wastes, which would have ended up in an authorized dumpster without recovery possibilities.

This project has been cofounded by the FEDER funds within the operative program of FEDER funds in the Valencian Community 2014-2020, the Generalitat Valenciana and IVACE.

AIJU (Technological Institute for Children’s Products and Leisure) has coordinated the project, and ITC-AICE (Institute of Ceramic Technology – Ceramic Industries Research Association) and AIDIMME (Metalworking, Furniture, Wood, Packaging and Related Technological Institute) have participated. In addition, a significant number of companies from the different industrial sectors involved have collaborated, contributing their vision and experience throughout all stages of the project.

The EcoMARSI project has had a total duration of 18 months.

Project Number: 22100056

Grant Agreement: IMDEEA / 2021/57

Duration: From 01/01/2021 to 30/09/2022

Coordinated in AIDIMME by: POCOVI MARTINEZ, SALVADOR

R&D Line: CIRULAR ECONOMY

For further information contact AIDIMME.

Visitors: 218