Introducing Sustainability Awareness within Production Planning

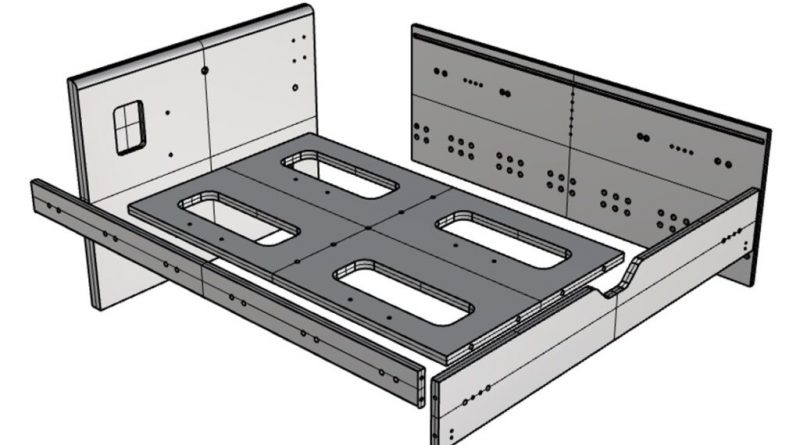

In E2COMATION project, DESIGNO s.r.l. has developed a Sustainability-driven Computer Aided Process Planning (sCAPP) tool in the form of a web application, where users are able to upload 3D models of parts they want to produce, and receive in return a Process Plan explaining the optimal machine selections within their shopfloor, tuned to user’s needs. This innovative tuning is achieved by providing the user the possibility to select if the Process Plans should be prioritising Productivity or Sustainability through the user interface, thus giving companies the ability to adapt to their current production objectives. With the help of our project partners, the tool has been applied in the furniture industry using real shopfloor data. The tool also provides as an additional auxiliary output, a report of part complexity analysis based on geometrical inspection and feature extraction algorithms performed on the uploaded parts, resulting in geometry data which is later automatically streamlined into manufacturing process information and decisions. DESIGNO has developed the tool to be easily transferable between different production plants, processes, user scenarios and industries. Example of part models, part complexity analysis and user interface for tuning the objective function can be seen in the images below.

For more information please contact with AIDIMME

Visits92