AIDIMME develops a metallurgic methodology capable of extracting up to 99% of metals from lithium batteries

• The method employed aims to substitute the current procedures, more destructive with the environment.

• The results of the initiative Recibat will aºllow the continuation of a research at the bottom of solving the imminent accumulation of batteries coming from electric vehicles.

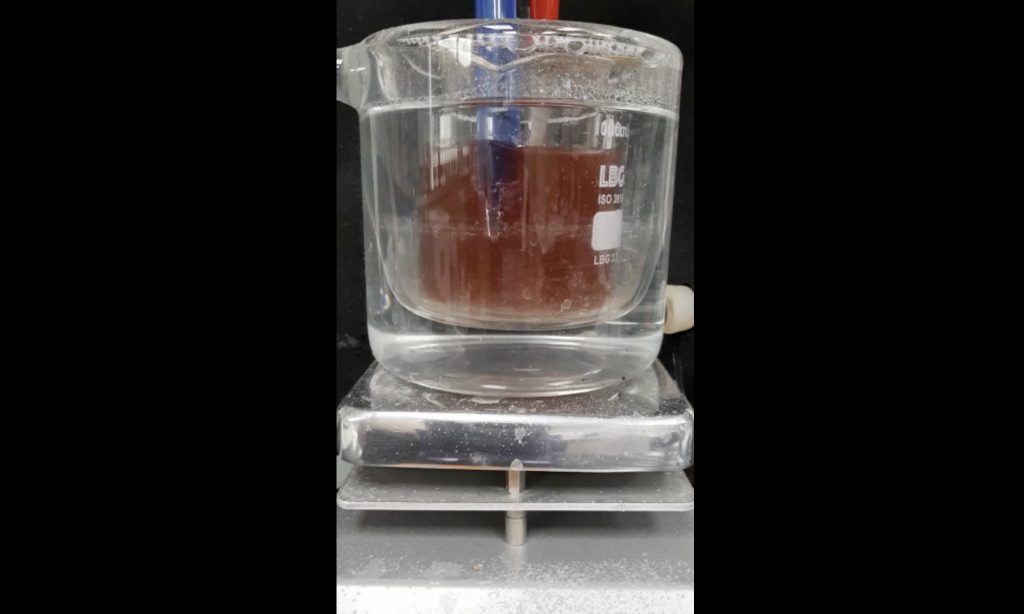

Experts in inorganic chemistry from AIDIMME’s technological institute have developed a methodology to extract the metals from electric vehicles’ lithium-ion batteries, managing to extract up to 99% of the former via electro-lixiviation of the cathode sheets with a previous ultrasound treatment.

Ultrasounds participate directly in the extraction of 99% of aluminum and facilitate the later process of electro-lixiviation for the rest of metals, obtaining 99% of efficiency for nickel, lithium and cobalt and, in a lesser degree for magnesium, which reaches a 44.2%.

Thus, the methodology proposes a pretreatment using ultrasounds at room temperature which provides a clean and intact Al sheet, and a later effective electro-lixiviation through a single-cell electrochemical process and a cathodic configuration in low concentration sulfuric medium.

On the one hand, this method avoids the current incineration recovery treatments: pyrometallurgical treatments (energy- intensive and contaminant, as they emit compounds such as sulphide or carbide). On the other hand, it avoids the hydrometallurgical processes, which are less aggressive but require a great amount of reactives (acid solutions, reductives and solvents, with long lixiviation processes, difficult reutilization and high cost).

Precisely, the main benefit of the process being investigated in the initiative “Recibat”, supported by the Valencian Institute for Business Competitiveness (IVACE), consists of a very significant reduction of the concentration of the lixiviation acid medium, without the need of reductors, which implies lower reactive consumption and a reduction of residual currents.

Other advantages of electro-lixiviation are the reduction of energetic consumption, working at 50ºC, instead of the 70ºC that come with conventional chemical lixiviation and the reutilization capacity of the acid solution in use (H2SO4).

According to the initiative’s promoters, promising results have been obtained to continue investigating this recycling pathway for lithium batteries. The next step is scaling-up the developed process in a pilot plant, as well as obtaining raw materials from the extracted materials, such as Li2CO3 (lithium carbonate) or nickel and cobalt catalysts.

Silvia Oyonarte and Francisco Bosch in collaboration with Ricardo Saiz

RECIBAT – METHODOLOGY FOR SUSTAINABLE RECYCLING OF METALS CONTAINED IN LITHIUM BATTERIES

Project Number: 22100061

Grant Agreement: IMDEEA / 2021/10

Duration: From 01/07/2021 to 30/09/2022

Coordinated in AIDIMME by: OYONARTE ANDRES, SILVIA

R&D Line: CIRCULAR ECONOMY

For more information contact AIDIMME.

Visitors 223